Optimus Books Welding Fixture Manufacturer et Factory in Sina

Company Development

- In MMXI, TTM in ShenZhen condita est.

- In MMXII, Movens ad DongGuan;Cohortatio cooperationis cum Magna Internationali Inc.

- In 2013 instrumentis gravioribus introducendis.

- Anno 2016, apparatu CMM magna-scalae introductae et 5 axis CNC apparatus;Cooperabantur cum OEM Ford Completa Porsche, Lamborghini et Tesla CF inceptis.

- In MMXVII, Movens ad current plant locus;CNC auctum est ab 8 ad 17 ponit.Top Talent Automotive Fixtures & Jigs Co.Ltd was established

- Anno 2018, cum LEVDEO automotive cooperatus est et lineam productionis automotionis complevit.4-axis summus celeritate CNC introductus est, tota Qty CNC pervenit XXI.

- In MMXIX, Dongguan Hong Xing Instrumentum & Die Manufacturer Co., Ltd instituta est.One stop service) Cum Tesla Shanghai et Sodecia cooperati sunt Germaniae.R&D novum laboratorium automationis aedificavit.

- In MMXX, OEM ISUZU in SA cooperatus est, perfecit RG06 One-Sistere Service.

- Anno 2021, Progrediens cum qualitate credendi ad faciendum inceptum mundi genus.

- Anno 2022, TTM munus Group in Dongguan urbe condita est, Nova CNC 4 axis*5 occasum, Novum Press 630 talenta, Hexagon Absolutum Arm.

- Anno 2023, TTM novam plantam aedificat ad reprimendam fixturam et glutinum fixturae negotium;addito uno 2000T prelo.

Reprehendo Fixture & Welding Jigs Factory (Total area: 9000m²)

Stamping Tools & Dies et Machined Partes Factory (Total area: 16000m²)

Products Description

| Product Name | Welding Fixture |

| Applicationem | Automotive CCB, Ante finem, WS Ver Link, Front Bumper etc. |

| Welding Type | Spot Welding, Arc welding, (CNC/Ess) Praecipua fixture welding |

| Pneumatica Component Brand | SMC, FESTO, TUENKERS, CKD, Fibulae Manuale |

| Electrical Component Brand | OMRON, Mitsubishi, Siemens, Balluff |

| Material (Block, Locating Pin) | 45# Steel, Cuprum, Steel |

| Operatio Via | Robot Welding, Manual Welding, Praecipua machina welding |

| Modi moderandi | Aeris Imperium (Pneumaticum Imperium Valvae), Electrical Control (Valve Solenoid), Manual, Nulla valvae solenoidei requiritur Provide iungo transitum |

| Via clamping | Pneumaticum, Manuale |

| Via communicatio cum Welding Cell | EtherCAT, PROFINET, CC-LINK |

| Communicationis Nullam Box | Arca electrica archa wiring via, genus nervum Velox, valvae Solenoidis insulae genus |

| Welding Fixture Base Type | Fixum in area, Positioner / Flip Tye |

| Limbis modo | Tubus unius tabulati, Flamma tubus retardans, Cuprum/Steel Tube |

| Fixture Superficies Curatio | Painting, Painting+Oxidization Black, Zinc-Coated, Powder Painting |

| Duc Tempus | II-IV hebdomadarum recensio consilio et consilio; 10-12 hebdomades pro fabricandis cum consilio approbatione 7-10 Days Working for shipping air; 4-5 septimanae ad Oceanum SORBITIO |

| Die Vita | Productio facultatem positum in elit |

| Quality Insurance | CMM Inspectionis Test cum Exempla Legamen ad Buy-Off Online video Interreti Conference Buy-Off Buy-Off Problematum solvendo |

| sarcina | Cistae ligneae ad exempla; pixides ligneae vel cursatores ad fixtures; |

Automotiveglutino adfixainstrumenta crucialorum in autocinetis processus fabricandis.Hae fixtures speciales ordinantur ad certas noctis et conventus variarum partium, quo facilius chassis, corpus tabulata, et alia critica partes.In hoc prospectu comprehensivo, aspectus automotivarum fixturarum conglutinationis clavos explorabimus, eorum momentum, considerationes, fabricationem, qualitatem temperantiam, earumque partes in industria automotiva.Momentum 1. Automotive fixtures welding:

Automotivi adfixae glutino partes vitales exercent in autocinetis productione ob varias causas: Subsecutio: Subsecutio- nem membrorum accuratam conservant, ducens ad constantem et accuratam weldis.Hoc criticum est de integritate structurae ac salute vehiculum.

Efficientia: Welding fixtures processus conventus accelerant, reducendo tempus et laboris impensas fabricandi.Quality Assurance: Tenendo partes in rectis positionibus, fixturae periculum errorum et vitiorum in ultimo facto minuunt.Constantia: fixtures constantes eventus liberant, cuiuscumque gradus peritiae operantis, quae essentialis est ad obtinendum qualitatem vehiculum uniforme.2. Design Considerationes: Designatio adfixa glutino automotiva est processus complexus, qui accuratam considerationem variorum factorum implicat: Vehiculum exemplar: Consilium fixture debet respondere speciei constitutioni et exemplarium vehiculi producti.Id requirit profundam intelligentiam vehiculi conventus requisita.Pars Positioning: In fixtura accurate collocare varias compositiones vehiculorum, ut tabulae corporis, sectiones chassis, et partes compages.Hoc definitum locum puncta implicat, machinationes clamitiones, structuras sustentant.Tolerantia et Alignment: Engineers considerare strictas tolerancias et noctis requisita ut partes perfecte cohaereant.

Materia Electio: Electio materiarum fixturae crucialis est.Sit durabile, calor repugnans, et rigidum processus glutino sustinere.Ergonomica: fixtures ad usum salutis et operantis otium dispositae sunt.Haec includit considerationes de accessu, visibilitate et ergonomica in operationibus glutino.3. Fixture Fabricatio:

Fabricatio glutino autocineti adfixa plures gradus implicat:

CAD Design: designatores singula 3D CAD exempla fixturae efficiunt, positionem, orientationem, puncta pro unaquaque componentium compaginatione denotantes.Materia Electio: Secundum specificationes designatae, materiae propriae, saepe ferrum vel aluminium, ad constructionem fixturae eliguntur.Vestibulum elementum: Singula membra, cum subsidiis structurae, fibulis et elementis positis, praecise conficiuntur machinis CNC machinis aliisque artificiis specialibus adhibitis.Welding and Congress: Periti welders et technici componentes conveniunt, ut accurate et secure cohaereant.Testis: Solitudo duram tentationem patitur ut occurrat alignment et tolerantiae quae ad accuratam glutino requiruntur.Hoc includit test components vehiculi conveniens.Calibration: Calibratio fixtura est ut integra maneat et integritatem structuralem retineat.4. Qualitas Imperium: Tuere signa alta qualitas per processum fabricationis fixturae essentialis est: Inspectiones: Inspectiones regulares fiunt ad comprobandum subtilitatem, durabilitatem et functionem partium fixturae.

Tolerantiae SCUTULATUM: Mensurae praecise et cohibetiones tolerantiae peraguntur ad confirmandum quod fixtura signa inquisita occurrat.

Noctis comprobatio: fixtures verificantur ut rectam alignment et orientationem pro conventu conservant.5. Munus in Industry Automotivi: Automotiva fixtures glutino integrales sunt processui fabricandi automotivi: Chassis Welding: fixtures accurate conservant noctis partium chassis, inter sectiones frameas et partes suspensionis.Corpus Panel Welding: Tabulata corporis tenent, ut fores, cucullas, et propugnatores, in positionibus rectis pro glutino, ad vehiculum altiore integritati structurae conferentes.Soam Welding: fixtures in junctura commissurae, artuum et nexuum adhibentur ad vincula valida et certa creanda.

Automation welding: Multis in casibus, glutino fixtures integrantur cellulis roboticis conglutinationis ad productionem automatam, ulteriorem efficientiam et constantiam augentem.6. Customization pro Automotivi Manufacturers: Automotivi glutino fixturae artifices saepe speciales faciunt in creando fixtures consuetudines formandas ad singulares necessitates singulorum automorum artifices.Hae fixtures ordinantur ad signa et requisita industria-specialia, et diversis exemplaribus vehiculi aptari possunt intra lineam producti corporis fabricantis.In fine, glutino adfixa autocineta componentia critica processus fabricandi autocineti sunt.

Solutiones (Turnkey Solutions Service)

Corpus In Alba Conventus Systems:

I, Complete Car Corpus Welding Line

2, Single Sta-solusWelding Cell

CCB ASSYWelding Fixture, Floor Pan ASSY Welding Fixture, Wheelhouse ASSY Welding Fixture, AB Ring ASSY AB Welding Fixture, Sedes ASSY Welding Fixture, Front Sedes Crucis Member Welding Fixture, Front End ASSY Welding Fixture, Dash Panel ASSY Welding Fixture, Cowl ASSY Welding Fixture Welding Fixture manufacturer, design company and factory.

ISO Management System For Welding Fixture

Our Welding Fixture Team

Commoda nostra

1.Rich experientia in fabricandis latis et inceptis procuratio.

2. One Subsisto Service ad instrumentum impressum, reprimendum fixturas, glutinosas adfixas et cellulas ad consequendum sincere et sumptus salutaris, communicationis commodum, ad maximizandos fructus emptoris.

3. Professional machinalis turmas ad GD&T finale pertinent inter singulas partes et conventum.

.

5. Valida facultas cum technicis auxiliis et societate cooperationis internationalis.

6.Big capacitas: Fixture Reperiens, 1500 occidit / annum; Fixture et Cellulae glutino, 400-600 ponit / annum;String Instruments, 200-300 sets/ year.

Plus quam 352 operarios habemus, 80% quarum machinarum technicarum seniores sunt.Instrumentorum instrumentorum divisio: 130 conductorum, solidorum solidorum divisio: 60 conductorum, Repressio fixturae divisionis: 162 conductorum, Nos habemus bigas professionales venditio & administratione project, diu terminus muneris transmarinis inceptis, ab RFQ ad productionem, sit amet, post venditiones, turma nostra omnes difficultates nostris clientibus in Lingua Sinica, Anglica et Germanica tractare possunt.

Maior Projects Usus Welding Cellae Et Welding Fixtures

| Maior Welding Fixtures Project(2019-2021) | |||||

| Item | Descriptio | Type | Nomen Project | Qty(Sets) | Annus |

| 1 | CCB WF | Arcus Welding | VW MEB31 | 60 | 2019-2021 |

| 2 | CCB WF | Arcus Welding | VW MEB41 | 10 | 2020 |

| 3 | CCB WF | Arcus Welding | VW 316 | 4 | 2020 |

| 4 | CCB WF | Arcus Welding | Ford T6 | 8 | 2021 |

| 5 | CCB WF | Arcus Welding | ISUZU RG06 | 3 | 2020 |

| 6 | CCB WF | Arcus Welding | Bcar, BSUV | 6 | 2020 |

| 7 | CCB WF | Arcus Welding | Bcar, BCAR | 7 | 2020 |

| 8 | Pan WF | Sopt Welding | SK326/0RU_K Karoq RU | 15 | 2019 |

| VW316/5RU_K Tarek RU (19003) | |||||

| 9 | WS Ver Link WF | Arcus Welding | WL/WS | 4 | 2019 |

| 10 | Crossmember Brackets WF | Arcus Welding | WL/WS | 12 | 2019-2021 |

| 11 | Ante Bumper WF | Arcus Welding | VW281 | 14 | 2019 |

| 12 | Chassis WF | Arcus Welding | ISUSU RG06 | 18 | 2019 |

| 13 | SL ASY and MBR and EXT ASY | Macula et Arcus Welding | Ford P703 | 25 | 2019-2021 |

| 14 | CCB WF et Wroking Cell | Arcus Welding | ISUSU RG06 | 6 | 2020 |

| 15 | Ante Sedem Cross Member WF | Sopt Welding | Volkswagen AG MEB316(20001) | 4 | 2020 |

| 16 | Pan WF et Grippers | Sopt Welding | AUDI/ PORSCHE PPE 41 (19017 Phase 1) | 18 | 2020 |

| 17 | Rota Domus WF et Grippers | Arcus Welding | Ford BX755 (19018) | 6 | 2020 |

| 18 | AB Ringo WF et Grippers | Arcus Welding | Ford BX755 (19018) | 14 | 2020 |

| 19 | Dash Panel WF et Grippers | Sopt Welding | South Africa Ford T6 (1728-1) | 10 | 2020 |

| 20 | Cowl WF et Grippers | Macula Welding | South Africa Ford T6(17028-3) | 6 | 2020 |

| 21 | Ante finem WF et Grippers | Macula et Arcus Welding | South Africa Ford T6(17025) | 10 | 2020 |

| 22 | Rocker WF et Grippers | Macula Welding | South Africa Ford T6 (19029). | 8 | 2020 |

| 23 | Pan WF et Grippers | Sopt Welding | AUDI/ PORSCHE PPE 41 (19017 Phase 2) | 63 | 2021 |

| 24 | Audi Bumper et Chassis WF | Arcus Welding | Ford P703&J73 | 36 | 2020-2021 |

| Maior Welding Fixtures Project(2022) | |||||

| Item | Descriptio | Type | Nomen Project | Qty(Sets) | Annus |

| 25 | Medio Channel Reinforcement WF | Sopt Welding | Vinfast VF36 | 8 | 2022 |

| 26 | Pan WF et Grippers | Sopt Welding | AUDI/ PORSCHE PPE 41 (19017 Phase 3&4) | 39 | 2022 |

| 27 | Pan WF | Sopt Welding et Projection Welding | Ford P703 PHEV | 29 | 2022 |

| 28 | Pan WF et Grippers | Sopt Welding | Porsche E4 Floor Pan (21050) | 16 | 2022 |

| 29 | Solum Tunnel WF | Laser vestigium | VW Floor Tunnel (21008) | 2 | 2022 |

| 30 | Sedes ASSY WF et Tooling | Arcus Welding | Sedes BYD ASSY | 40 | 2022 |

| 31 | Pan WF | Macula et Arcus Welding | Ford Refurbishment | 24 | 2022 |

| 32 | CCB WF | Arcus Welding | VW Cyclone CCB (21037). | 10 | 2022 |

| 33 | CCB WF | Arcus Welding | VW MQB37(22022) | 16 | 2022 |

| 34 | A&B-Columna WF | Macula Welding | GS2203 | 8 | 2022 |

| 35 | Robot Cell Base | NA | VW Cyclone | 4 | 2022 |

Welding Fixture Vestibulum Centre

Omnes variae magnitudinis glutino fixturas condere possumus cum magna magnitudine, sicut magnas CNC Machinas habemus.Cum variis instrumentis mechanicis ut molendis, stridoribus, filum secandis machinis et exercendis machinis, processus processus efficaciter et accurate moderari possumus.

25 mutatoria cnc cum 2 subcinctus cursus

1 Set of 3-Axis CNC 3000* 2000*150

1 Set of 3-Axis CNC 3000* 2300* 900

1 Pone 3-Axis CNC (IV)* MMCD* 900

1 Pone 3-Axis CNC (IV)* MMCD* 1000

1 Set of 3-Axis CNC 6000*3000*1200

4 Pone 3-Axis CNC DCCC*D*530

IX Pone III-Axis CNC 900*DC*600

5 Pone 3-Axis CNC MC*DCCC*D

1 Pone 3-Axis CNC 1300*700*650

1 Pone 3-Axis CNC 2500*MC*800

5 Axis CNC -Machine

4 Axis CNC -Machine

Fixture Conventus glutino Centre

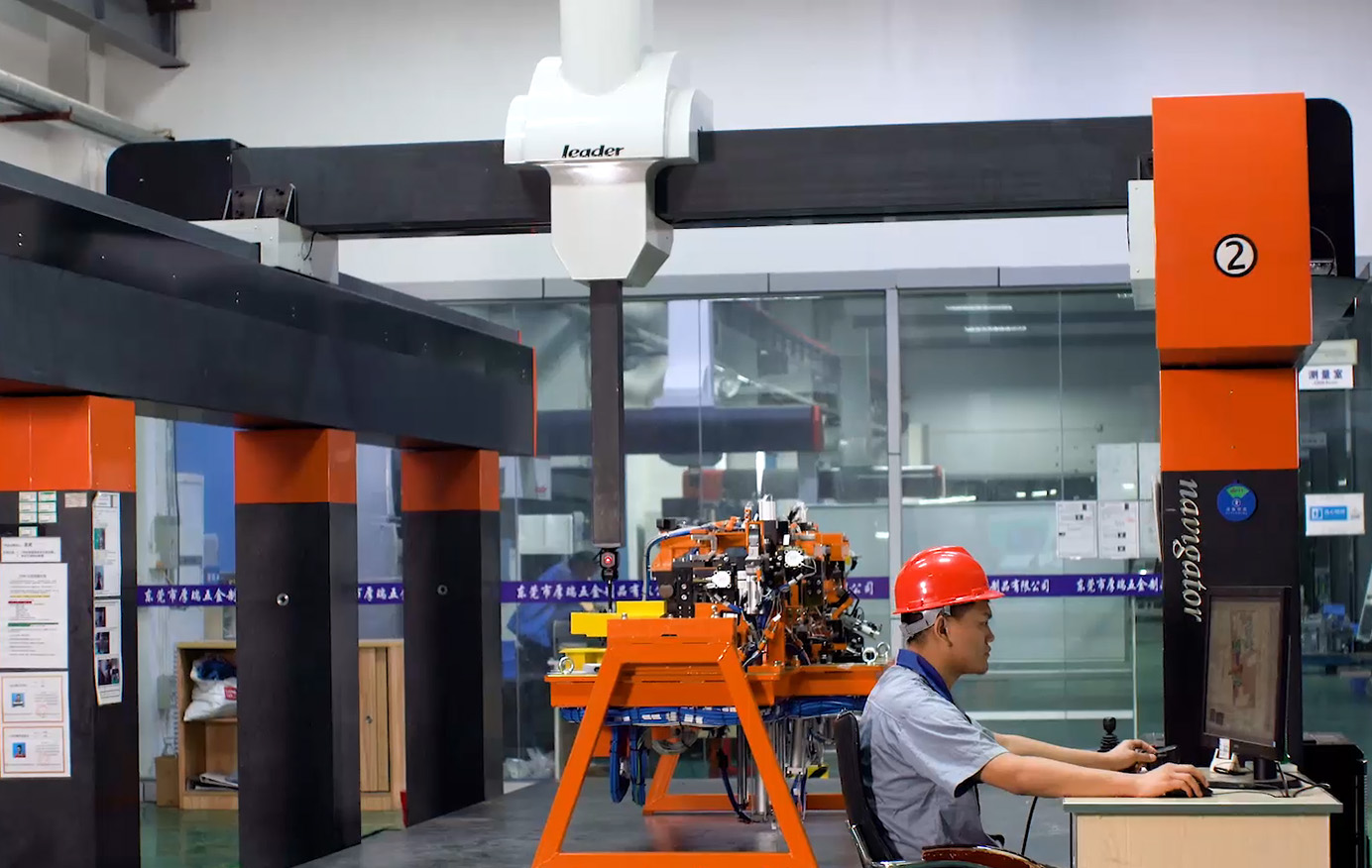

CMM Measurement Centre For Welding Fixture

Our boni institutores curabunt omni tempore in omni programmate habebimus.Possumus omnem postulationem a emptore, maximam etiam satisfactionem habere in CMM.

III Sets CMM, II Shifts / Dies (10hrs per subcinctus Mon-Sat)

CMM, 3000* 1500* 1000 , Dux CMM, 1200*600*600, Dux Blue-lux Scanner

CMM, 500*500*400, Hexagon 2D Projector, duritia Tester

.png)

.png)