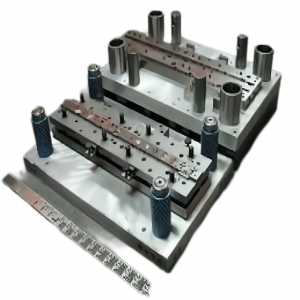

Welding Fixture For Cross Member WS Spring Link

Video

Applicationem Agri

Automotive industria qualis imperium

Automotiva productio rectae capacitatis amplio productio

Specification

| Fixture Type: | Arcus Welding |

| Magnitudo: | 1800x1300x900mm |

| Pondus: | 125KG |

| Materia: | Principalis Constructio: metallum Support: metal |

| Superficiem treatment: | Base Plate: Chromium Electroplating et Nigrum Anodized |

Product Details

Prooemium Detailed

Haec est batch ligaturae fixturae WL Cross Member WS Spring Link, prorsus in 2 occidit, fecimus pro nostro Canadae emptoris. Ver monax scapus cylindricus fixtura in machina molaria inauguratus est terebra vel circumdatio circumdatio.monax in cincinno nucem insere ac leniter cochleare lock nucem cum verna monax in scapus, iungo vel fusum.Pendere elasticitatem chalybis elastici ad obstringere, laxare fibulas opportunas, plerumque ad lucem clampendam, mediae sarcinae instrumenta incisionis adhibita.Saepe ad instrumenta secandi usus est ut molendina finis, terebra frenum, tapsus, reamatores et centri terebras.Mutatione clamping per varias collectas mutando. Cum clamping, stamina pars monax vernae, nucis cincinnus et superficies et superficies pyramidis positionis purgari debent.Per institutionem chuck et nucis cincinnae, chuck et cincinnus nucis cuidam Angulo iugo debent, et deinde in cincinno foramen nucis cincinnae collocari.Noli uti clavis torques extensorum potens nimis stricta est, ne instrumentum meteoritarum malum et fixture.

Operationis O

1. accepistis acquisitionem ordinis---->2. Design---->3 confirmans extractionem / solutiones---->4. Pone materiae---->5. CNC---->6. CMM---->6---->7. CMM-> 8. Inspectionis---->9. (3 part inspection si opus est)---->10. (internus / mos in situ)---->11. Sarcina (ligneus arca)---->12. Delivery

Vestibulum Tolerantia

1. Planities Basis Plate 0.05/1000

2. Crassitudo Base Plate ±0.05mm

3. Locus Datum ± 0.02mm

4. Superficies ± 0.1mm

5. Reperiens paxillos et foramina ±0.05mm

Processus

CNC Machining (Milling/Conversus), Grinding

Electroplating Chromium et Nigrum Anodized Treatment

Design Horae (h): 40h

Horae aedificate (h): 150h

Regimen quālitātis

CMM (3D Coordinate Machina mensurans), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Tertia Factio Certificatio facta a ShenZhen Argentea Basis Testis Technologiae Co., Ltd , ISO17025 Certified

.png)

.png)